-

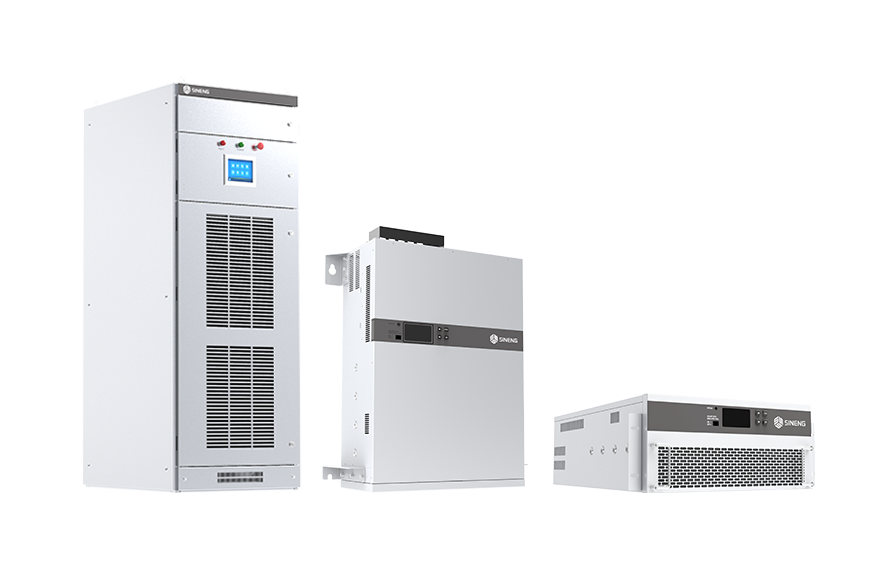

Products

-

-

-

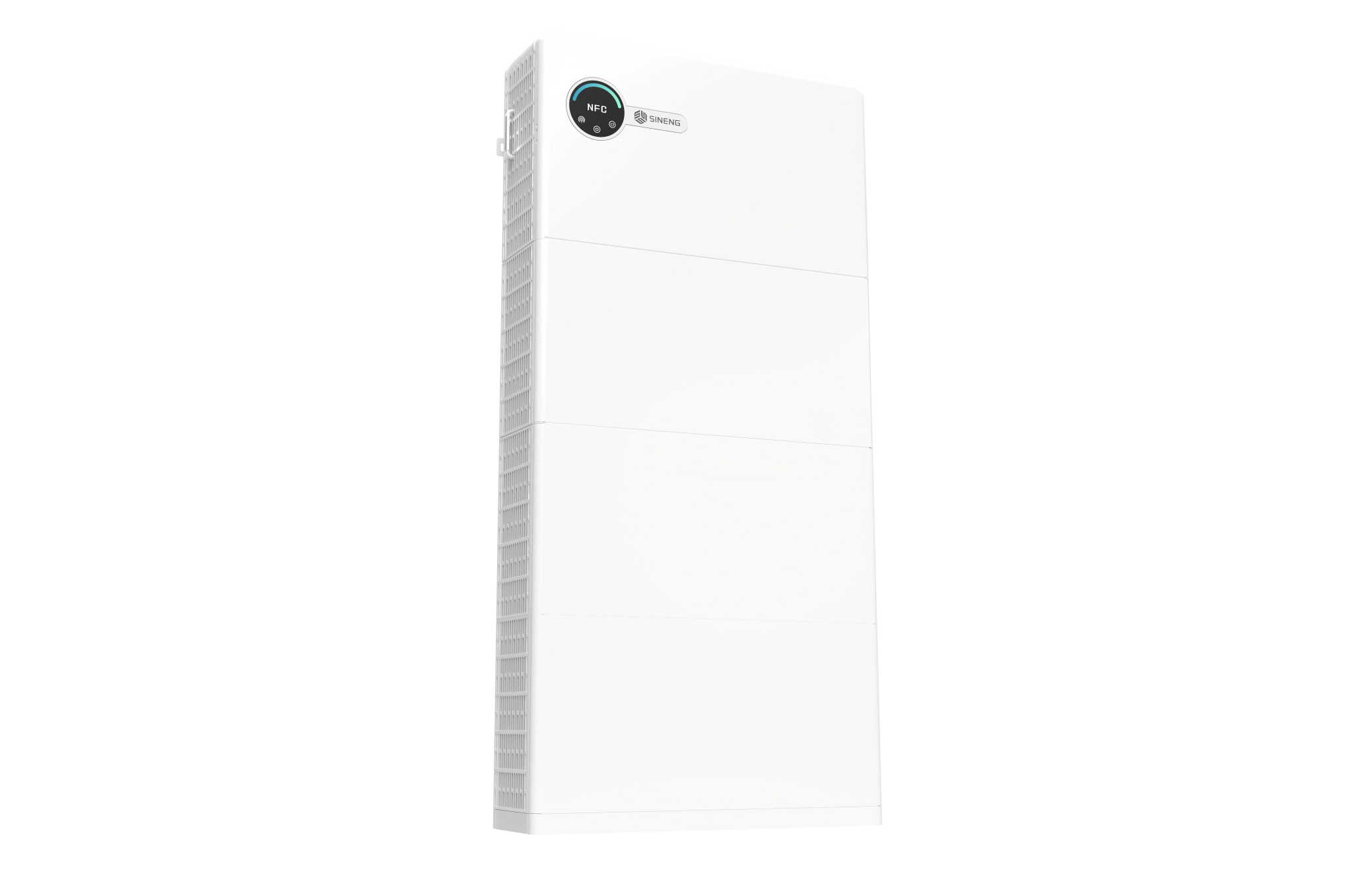

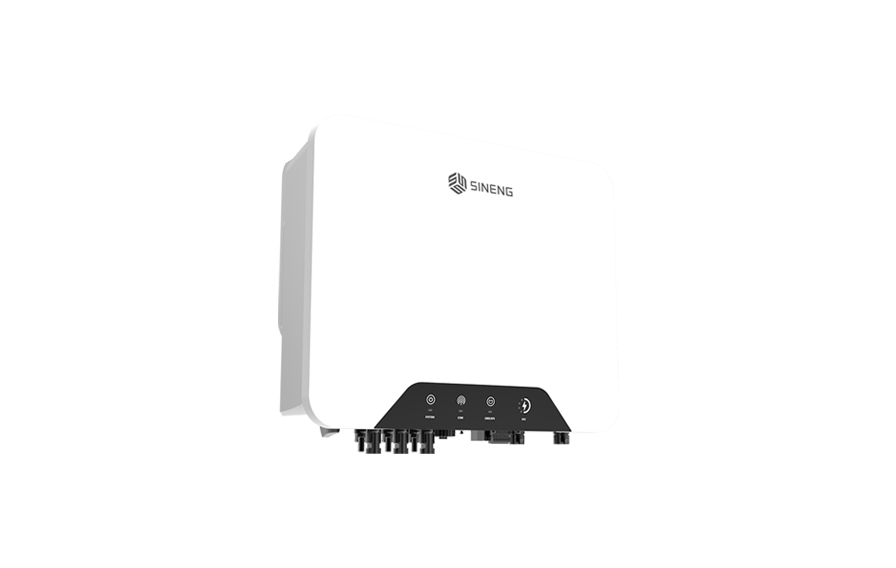

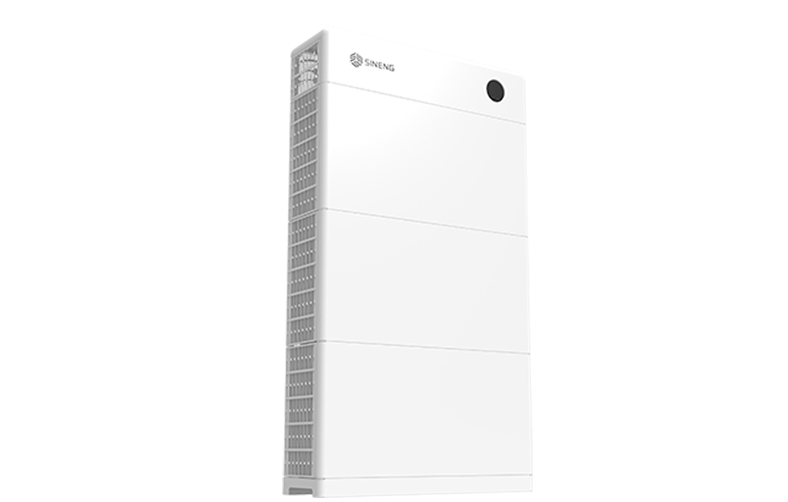

Residential All-in-One

-

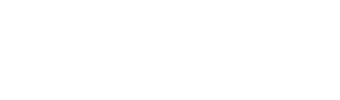

SN3.0/3.6/4.0/5.0/6.0HS

-

SN5.0/6.0/8.0/10/12/15HT

-

SN20/25/29.9/30/33HT

-

RHP7.0/10/14/17/21-G1

-

EB-6.4~25.4KWH-HA

-

-

-

EH-0200/0215-HA-M

-

EH-0250-HA-M

-

EH-0430-HA-M

-

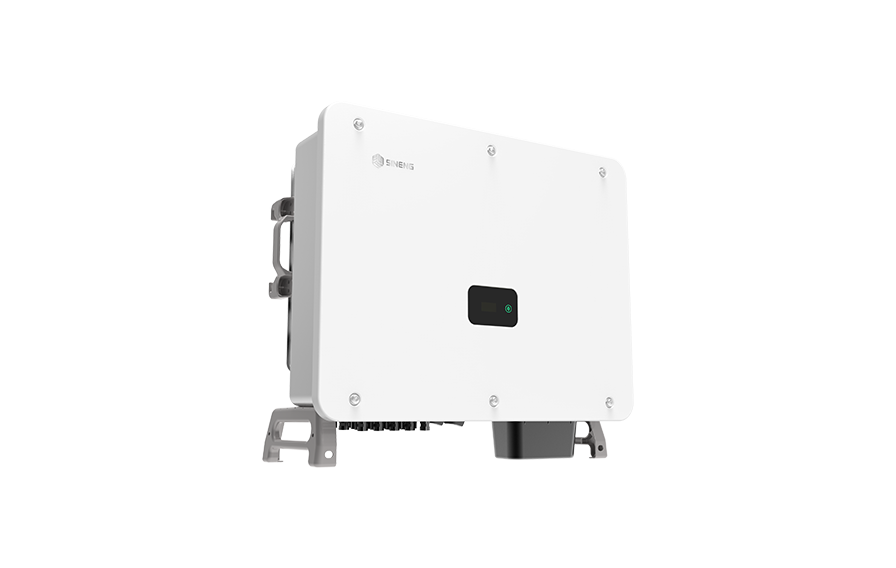

EH-2400/3200-HA-MR-35

-

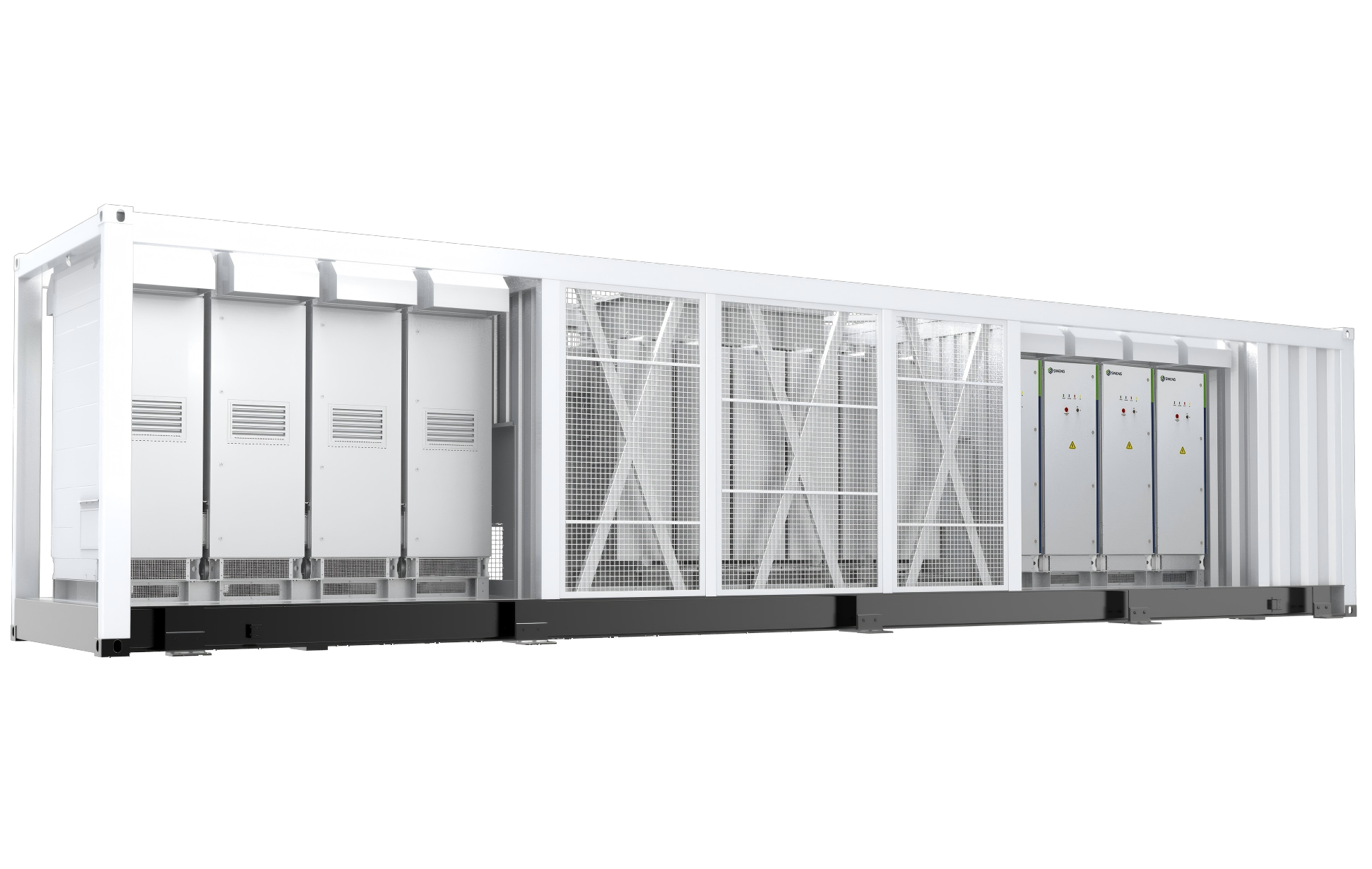

EH-8600-HA-MR

-

EH-12500-HA-MR-10~33

-

-

-

EH-1250-HB-UD

-

EH-1725-HB-UD

-

EH-1725/2000-HA-UD

-

EH-3450/4000-HA-UD-35

-

EH-5000-HB-UD-35

-

EH-6900/8000-HA-UD-10~33

-

EH-10000-HB-UD-10~33

-

-

English (Global)